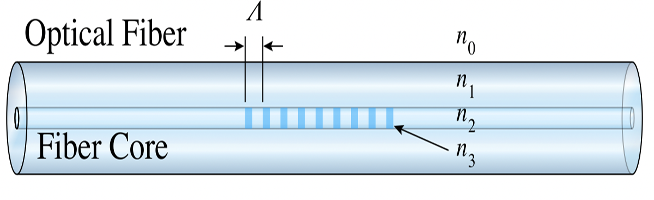

Figure below shows a schematic diagram of a fiber core with a Fiber Bragg Grating (FBG) inscribed (the fiber core diameter is 9 microns). People use UV phase mask irradiation, Femtosecond laser point-by-point writing or other processing methods to form countless weakly reflective surfaces with the same spacing in the core part of the fiber, these weakly reflective surfaces are called fiber gratings, and the distance between each weakly reflective surface is called the grating pitch or grating period (we generally use the symbol Λ to denote it - remember this symbol, we will need it later).

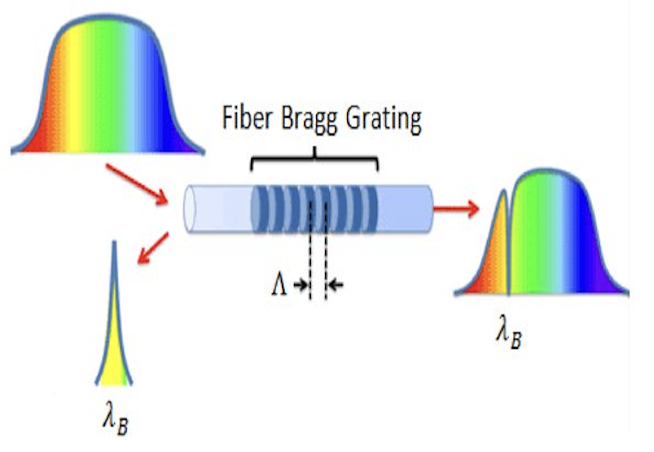

The basic sensing measurement can be carried out using the above-mentioned fiber bragg grating, and its principle is shown in Figure below:

Shown in the above, the broadband incident light enters the fiber from one end of the grating sensor, and encounters the fiber bragg grating (FBG), most of the wavelength of light directly passes through the FBG as transmitted light, and a small part of the light of special wavelength is reflected back (please pay attention to this special wavelength, this is the object we want to detect every time, we use λB to represent it ). λB is directly related to the grating pitch (grating period) Λ we mentioned earlier. The mathematical expression to characterize the relationship is: λB = 2neffΛ, where λB is the reflected wavelength, neff is the refractive index of the fiber core, and Λ is the grating distance (grating period).

Next, the reflected light enters the FBG Interrogator (not marked on the figure), and the wavelength signal λB is demodulated. Because the FBG sensing device is connected, we can get a different test wavelength signal λB every moment. Through the previous mathematical expression, we can know why the wavelength signal λ returned at the next moment has changed (the amount of change is represented by ΔλB)? The fundamental reason is that the grating pitch (grating period) Λ of the fiber grating has changed (the amount of change is characterized by ΔΛ).

Well, at this point we can jump out of the mathematical notation, switch back to the real environment and imagine, what can cause the grating pitch (grating period) Λ to change?

The first possible reason is force: you give the FBG a tension, it will become longer, you give the FBG a pressure, it will become shorter;

The second possible reason is temperature: the FBG expands when heated, and it gets longer, and when the FBG contracts when it cools, it gets shorter.

In this process, people have linked the wavelength signal that can be accurately detected with three basic physical parameters, namely force (tension and pressure), length (longer and shorter) and temperature (heated and cold), Therefore, the basic physical parameters that can be directly measured by the FBG sensors include stress, strain and temperature.

The FBG temperature sensor from AtGrating, in the vicinity of our common 1550nm C-band, the sensitivity (resolution) of the FBG temperature sensor is about 11pm/℃, which means that the measured object or the measured environment is for every 0.1℃ change in temperature, the reflected wavelength of the fiber grating temperature sensor changes by 1pm. At this point we can say that the sensitivity (resolution) of the fiber grating temperature sensor is 0.1℃.

It should be further pointed out that the sensitivity or resolution of the FBG temperature sensor we are talking about is 0.1℃. This statement is more from or limited by the fiber grating interrogator (not limited by the sensor itself), if a interrogator with higher resolution is used, so that it can detect wavelength changes below picometers, the sensitivity or resolution of the fiber grating temperature sensor we define here will also be correspondingly improved.

Fiber Bragg Grating (FBG) Temperature Sensor is a kind of sensor that uses Fiber Bragg Grating as a sensitive element and cooperates with a FBG Interrogator to detect and monitor the temperature of the measured object and the environment.

FBG Temperature Sensors are also known as FBG Thermometers, Fiber Bragg Grating Temperature Probes etc. In terms of product classification, it is a kind of Fiber Bragg Grating sensor, and it is also a kind of fiber optic sensor; and in terms of product function, it belongs to a kind of temperature sensor.

According to the different temperature measurement grades of FBG temperature sensors, it can be divided into high temperature FBG temperature sensors, normal temperature FBG temperature sensors, low temperature FBG temperature sensors and other types.

According to the number of FBG temperature measurement points packaged in the FBG temperature sensor, it can be divided into single-point FBG temperature sensor, multi-point FBG temperature sensor (string FBG temperature sensor, quasi-distributed FBG temperature sensor) and other types.

According to the different packaging materials of FBG temperature sensor, it can be divided into seamless steel tube FBG temperature sensor, ceramic FBG temperature sensor, polymer FBG temperature sensor and other types.

FBG temperature sensor is the most widely used of all fiber optic sensors. It can be widely used in various independent temperature measurement environments, including various mechanical and electrical products, industrial production, petroleum and petrochemical, electric power, railway, military, aviation , aerospace, metallurgy, chemical industry and other fields of temperature measurement, temperature detection and monitoring, and can be applied to the temperature compensation of various optical fiber sensors.

Latest News at ArGrating FBG Sensing

2023-Aug-12

+

2023-Jun-01

+

2023-May-15

+